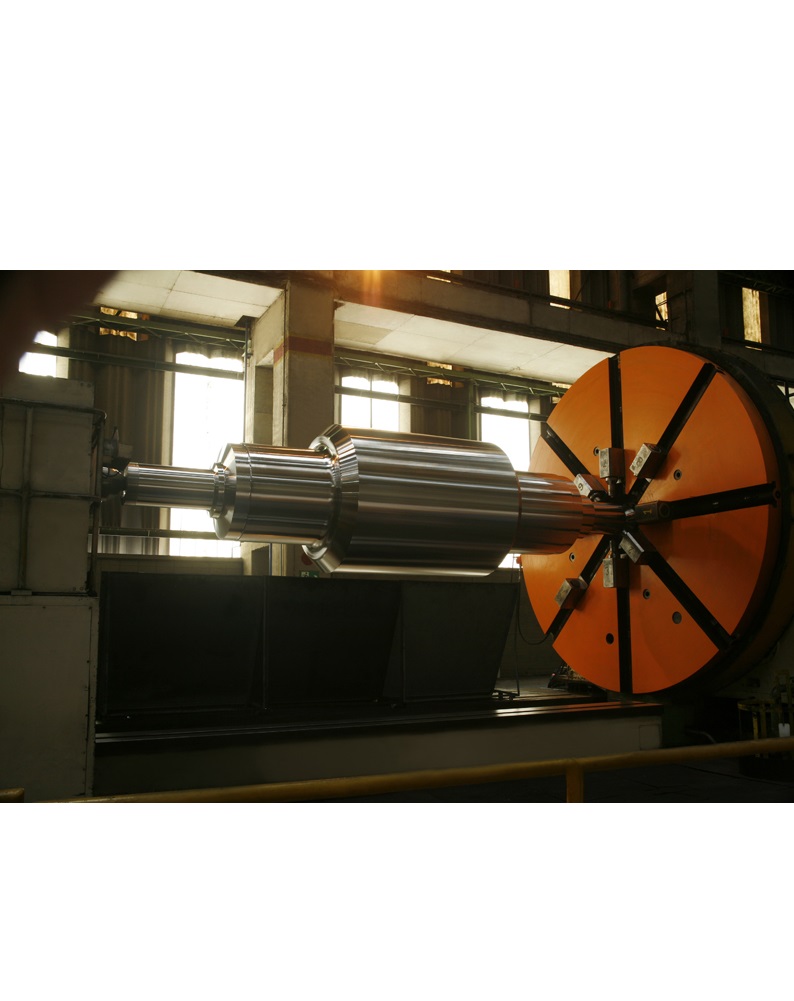

Durability and Reliability

Rolls are manufactured from degassed steel by means of a vacuum process that presents a high level of purity. Forging occurs in hydraulic presses to guarantee high toughness. They are used in continuous hot-strip, steckel-type and cold strip mills, withstanding the most severe rolling conditions. Product development guarantees a performance which is far superior to that of cast back-up rolls. The microstructural homogeneity of these products allows for applications involving high hardness ranges and high resistance.

How to buy

To purchase Gerdau Summit rolls for flat applications, you may contact us at the following e-mail: mkt@gerdausummit.com

Technical Specifications +

| VC4A (Group I) | VC4HM-1 (Group II) | VC4TS (Group III) | |

|---|---|---|---|

| 3% Cr | 5% Cr | 5% Cr, Mo enhanced | |

| C | 0,40 - 0,50 | 0,40 - 0,70 | 0,40 - 0,50 |

| Si | 0,10 - 0,45 | 0,10 - 0,60 | 0,20 - 0,50 |

| Mn | 0,53 - 0,88 | 0,40 - 0,80 | 0,40 - 0,80 |

| Cr | 2,60 - 2,10 | 4,00 - 5,00 | 4,00 - 5,50 |

| Mo | 0,40 - 1,08 | 0,20 - 1,00 | 4,00 - 5,50 |

| V | 0 - 0,15 | 0 - 0,30 | 0,20 - 0,40 |

| Resistance Limit (MPa) | 1200-1500 | 1250-1600 | 1250-1600 |

| Yield Limit (MPa) | 1100-1400 | 1200-1550 | 1200-1550 |

| Hardness (LD) | 655-735 | 655-760 | 730-800 |

Chemical composition in percentage of mass (% wt)